This installment was written by Mark, but I really needed to insert some of my own comments about this experience. You will see my comments starting with a blue vertical line followed by Marlo:

Throughout the first half of 2018, we worked with our architect, Cordero, on the plans for the remodeling and reconstruction of the hotel. We had explained our wish-list to Cordero, and he did a masterful job translating those wishes into a design that was simply jaw-dropping. We finalized the blueprints after several iterations, and Cordero took care of getting all the permits and approvals.

Just a few weeks before we were scheduled to close the hotel and begin construction, we met with Cordero in his office to work through some last logistical and planning details. Cordero opened the meeting by saying he had some very bad news.

“The plans we developed are not possible to build,” he said.

“What do you mean?” Marlo and I replied, aghast.

Marlo: Sheer panic rising in my chest…

“I’ve looked all over Costa Rica, and there are no cranes that can access the site, and erect the building as we have designed it,” Cordero explained.

We were stunned to say the least. Just a few weeks from starting construction (and closing the hotel for the scheduled 5+ months), Cordero said we would need to start the design process all over again.

Marlo: Huh? OMG-we don’t have time!

There were several problems that Cordero had identified.

First, the hotel is located several miles up an extremely steep, winding, and narrow dirt road. Large commercial cranes would never be able to climb the mountain to get to the site.

Second, the hotel is built on a slope so any crane would have to be either (1) small and light enough to operate from within the building, or (2) able to operate on the steep slope without instability.

Lastly, the new design of the hotel included very large and heavy steel beams that would form a sort of floating roof about 20 feet off the ground. There was no way to lift these heavy beams without a crane.

Marlo: Holy shit! And ‘we’ didn’t think of this sooner??

I am a mechanical engineer by education, but I had never done any real engineering in my career. As I sat in Cordero’s office absorbing this shocking news, I kept thinking that there HAD to be a way to engineer a solution. Then I had a crazy idea - we could just build our own crane!

Marlo: Mark has had many a crazy idea in our time together—this was right up there with, ‘Hey let’s buy a hotel in Costa Rica!’

We could do a custom design specifically for this application. Stupid, right? Cordero laughed when I explained my idea. He didn’t think I could possibly be serious. I told him to give me a couple days to think about it.

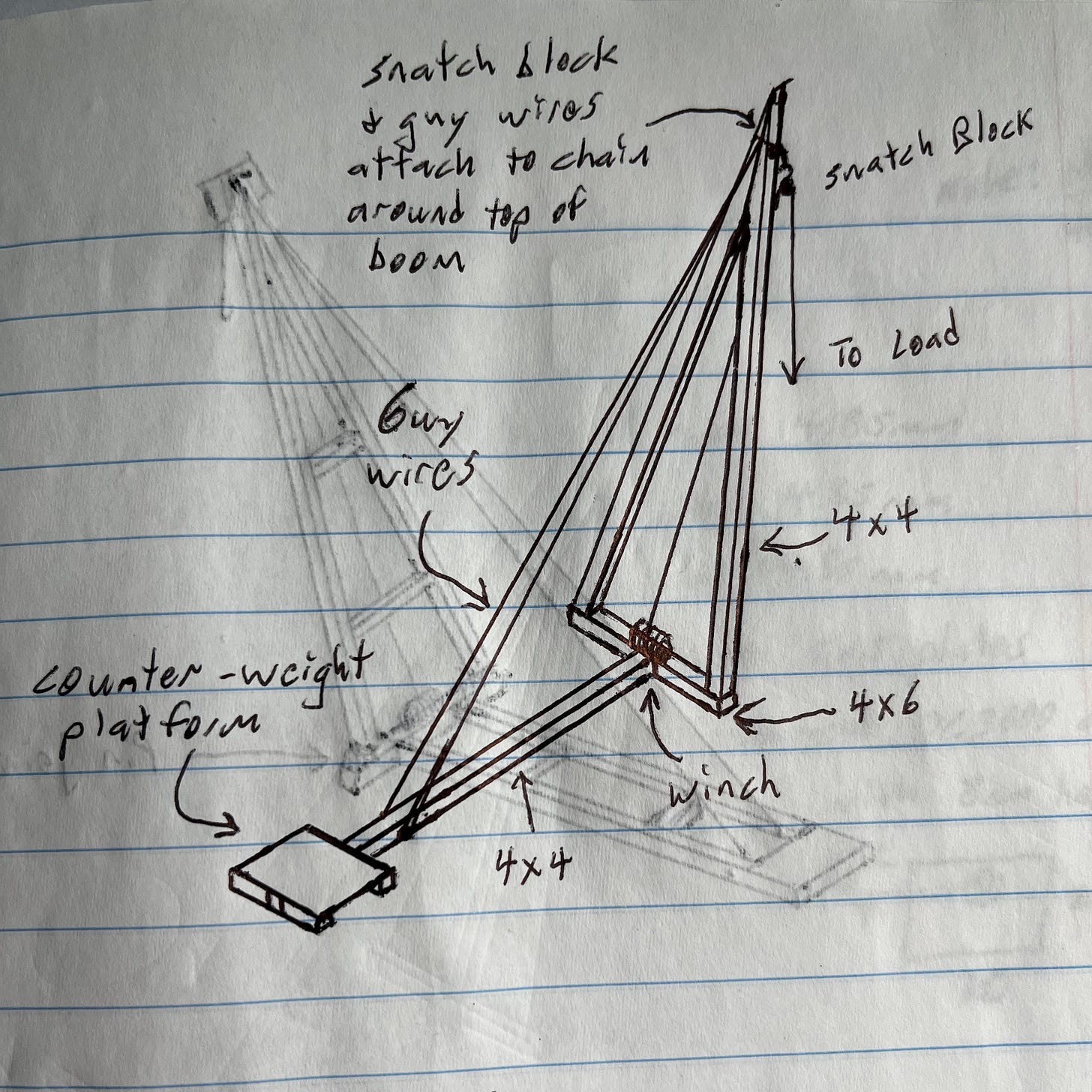

Back at the hotel, I started sketching designs and thinking about all the materials and equipment I would need to make a crane. The biggest issue would be finding everything I needed in Costa Rica.

As soon as I was reasonably confident it could be done, I called Cordero. I told him that I would take complete responsibility for making the crane. We agreed to absolve him of any liability if there were any delays or other construction problems related to the crane. He still thought I was crazy, but he agreed to trust me.

Now it was time to do a detailed design. Luckily, I have a nephew who owns a crane business in Kentucky. I sent my sketch to him, and he replied, “Uncle Mark, as I see it there are probably 3 or 4 ways someone will likely get killed if you make a crane like this.”

Okay, so my first attempt wasn’t perfect. He gave me some suggested design changes and I went back to the drawing board. After my second design attempt, my nephew upgraded by chances of a fatal accident to 50/50. I finally got his approval with my third design.

Marlo: Let me say that Mark is smart. He likes a challenge, and he likes math. For weeks, in the middle of the night, I’d find Mark at the kitchen table working on sketches of crane designs. He had pages and pages of crane sketches. AJ, our former manager, would constantly ask, ‘How does he know how to do this?’ Mark would tell him, ‘It’s just math.’ But, he had never designed and built a crane so…

Getting all of the materials and equipment to actually make the crane was the hardest part. The basic steel, cabling, and fasteners were easy to find, but other parts like the high strength snatch blocks (pulleys) and a powerful hoist were harder.

Do you know the difference between a hoist and a winch? Neither did I. A winch is designed to pull things horizontally and doesn’t have good brakes built into it. A hoist looks EXACTLY the same as a winch, but it is designed to lift things vertically and has built-in brakes to keep things from falling down – and killing somebody.

We needed to lift steel beams 20 feet off the ground (vertically!), not drag them along the ground (horizontally!). Everyone in Costa Rica wanted to sell me a winch. I kept telling them we needed a hoist. They would just roll their eyes and tell me they are the same thing.

I finally ordered the hoist from the U.S. and had it shipped to Costa Rica.

Now a quick aside about the magic of pulleys. You probably studied this in high school physics and immediately forgot all about it. With one pulley, you can lift something that weighs 100 pounds by applying 100 pounds of pulling force to the cable or rope you are using. With two pulleys, you can lift that same weight with only 50 pounds of pulling force. With three pulleys, you can lift it with 33 pounds of force. It is truly magical. I used three pulleys in a “block and tackle” system on my crane to reduce the load on the cable and the hoist.

Marlo: Huh? Did that go over everyone’s head or just mine? Again, he’s smart…and a little geeky.

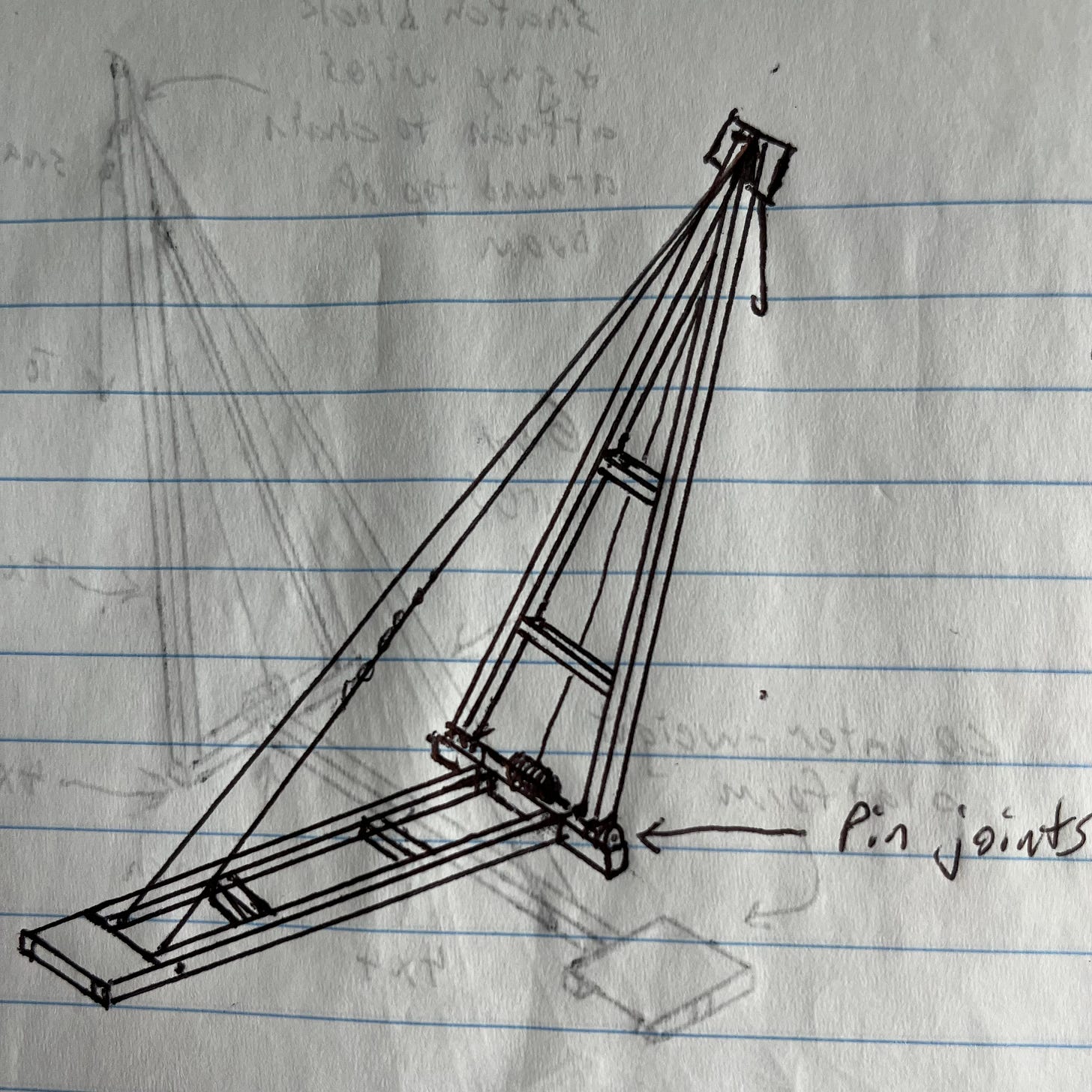

After purchasing all the materials and equipment for the crane, we hired a metal fabricator in Costa Rica named Marco to build it. He had a shop about an hour away from the hotel. This guy was adventurous like me, so he loved the idea. Cordero also hired Marco to do the erection of the steel building structure – using my crane. Marlo and I drove over to his shop when he was almost finished making the crane to check on the progress. It was so weird to see my sketch brought to life. The thing looked huge, and it weighed a LOT.

When Marco delivered the crane to the hotel, I had set up a test station to make sure it really worked. We filled a 1000 liter water tank and rigged it up with straps to see if the crane was able to safely lift it. The tank weighed about 2,200 pounds when filled with water so this would be a good test.

When setting up the crane for the test, we discovered that the crane was so heavy, we couldn’t assemble it in an upright position. We needed a crane to lift the crane! Fortunately, a backhoe happened to be driving by (only in Costa Rica!!) and the driver used his shovel to lift it up for us. That allowed us to run the test this time, but we would need another solution when construction started.

Marlo: We (read: me!) were on pins and needles for this test. We had now spent weeks up to the hotel closure working on designing and building the crane. Mark was so sure it would work that we continued with our planned schedule and had begun the demolition of the hotel. Yes, the demolition of the hotel-you read that correctly! But if this crane didn’t work, we would have to go back to the drawing board to redesign the hotel. We would lose more time, have to delay the whole project; meaning more time closed and lost revenue! I am Mark’s biggest fan, but I asked him about a billion times during this, “Is this going to work?”

It worked! The crane effortlessly lifted the water tank! I recorded a video for my nephew to share the good news – no fatalities yet.

I went back to my sketch book and designed a sort of lifting device that would allow the crane to lift itself up using the power of the hoist. A couple of the maintenance guys from the hotel built the device for me, and we went to test it on the crane. I wasn’t 100% confident this device I had just dreamed up would work, so I told all the guys to stand back while I turned on the hoist to see if the crane could lift itself up.

The vertical portion of the crane started rising slowly from the horizontal part. It got about 6-8 feet off the ground when there was a loud snapping noise and the heavy vertical part slammed back to the ground – crushing several cinder blocks that had been supporting it moments before. I shuddered at the sight of those crushed cinder blocks and breathed a sigh of relief that everyone had been standing at a safe distance.

A metal ring we had purchased at the local hardware store had broken. We fashioned a stronger metal ring using a thick piece of steel rebar and ran the test again to lift the crane. With all the guys again safely out of the way, we watched as the crane rose all the way up to its vertical position. What a relief.

We were now ready for construction!

I was so fearful of someone getting hurt by the crane, that I appointed myself as the sole operator. I told Marco, Cordero, and my employees that nobody was allowed to operate the crane except me. Over the next two weeks, we erected the entire building structure without incident. Every time we completed a lift of a steel beam, the entire crane had to be disassembled, moved, and re-assembled in the next location.

It was so heavy it took six men to move each of the crane’s two main components. The guys started affectionately calling the crane “La Ballena” – the whale.

We finished constructing the main hotel building structure a week ahead of schedule.

And nobody died.

OMG I have so much anxiety right now, even though I should be in actual awe of Mark's genius. Sheesh, Marlo, I think you bit off way more than you bargained for. I would have been a total complete wreck during this process. Kudos to you all!

Mark is a genius